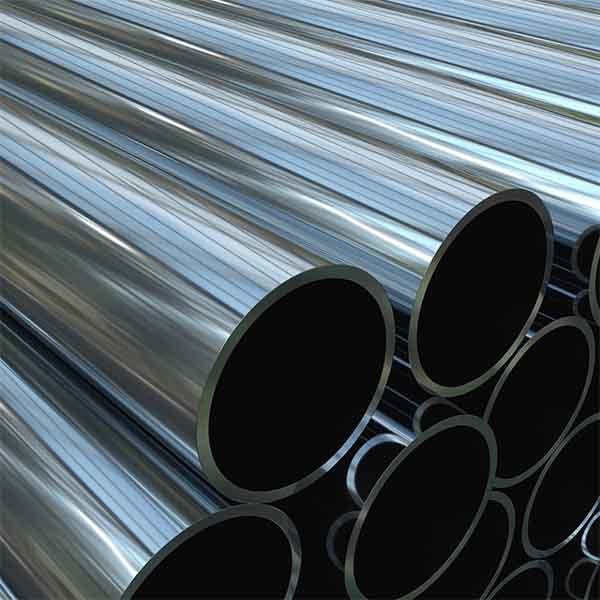

Chrome-plated steel pipe

Classification :

Steel Pipe

PRODUCT DETAILS

Product Description

The chromium plating layer has a very high hardness. Depending on the composition of the plating solution and process conditions, its hardness can vary within a wide range of 400 to 1200HV. The chromium plating layer has good heat resistance. When heated below 500°C, its gloss and hardness do not change significantly. When the temperature exceeds 500°C, it begins to oxidize and discolor, and when the temperature exceeds 700°C, the hardness begins to decrease. The friction coefficient of the chromium plating layer is small, especially the dry friction coefficient, which is the lowest among all metals. Therefore, the chromium plating layer has good wear resistance.

The chromium plating layer has good chemical stability and does not react in alkali, sulfide, nitric acid and most organic acids, but it can be dissolved in hydrochloric acid (such as hydrochloric acid) and hot sulfuric acid. In the visible light range, the reflective ability of chromium is about 65%, which is between silver (88%) and nickel (55%). It is better than silver and nickel because chromium does not discolor and can maintain its reflective ability for a long time when used.

Parameters

| Product name | Chrome-plated steel pipe |

| Material | A53 B, St37-2, St52-4, |

| Wall thickness | 1mm-20mm |

| Outer Diameter | 21.3MM-1620MM |

| Physical Property | API 5L, ASTM A53, ASTM A671-2006, ASTM A252-1998, ASTM A450-1996, ASME B36.10M, BS 1387 |

| Grade | A53 B , ST37-ST52 |

| Surface Treatment | Chrome plating |

| Pipe Ends | Plain end/Beveled,protected by plastic caps on both ends, cut quare,grooved,threaded and coupling,etc. |

| Certificate | API 5L,FM,UL, CE, |

| Application | Suitable for fire piping system,air,gas,oil and so on |

| Buyer's drawing or designs are available |

Production Process

Chrome plating method

1. Conventional chromium plating: Similar to usual electroplating, the steel pipe is immersed in the electroplating bath. After connecting the anode and cathode, current is applied in the electrolyte to reduce the chromium ions plated on the steel pipe to chromium metal deposition. on the surface of the steel pipe.

2. Rolling chromium plating: Place the steel pipe in a chrome plating machine for rolling, and chromium ions are deposited under the action of electric current in the plating solution, so that a chromium plating layer is obtained on the surface of the steel pipe.

3. Vacuum chromium plating: Place the steel pipe in a vacuum chamber, and through physical vapor deposition at high temperature, chromium ions in the air are deposited on the surface of the steel pipe to form a chromium layer.

Shipping Packaging

products are sold all over the country and Europe, America, the Middle East, Africa and Southeast Asia and other global more than 100 countries,and the world's top 500 enterprises to establish a deep cooperative relationship, well received by customers.

Application description

Chrome-plated steel pipes are widely used in machinery manufacturing, automobile manufacturing, petrochemical industry, aerospace and other fields.

Customer visit

We uphold the customer-centric business philosophy, and win the trust of customers with high-quality products, considerate service, and punctual delivery. We sincerely welcome domestic and foreign merchants to visit us, seek common development, and create brilliance together!

INTENTION INFORMATION

Related Products

GET A FREE QUOTE