steel support

Classification :

Section steel

PRODUCT DETAILS

Product Description

Steel supports refer to the use of steel pipes, H-shaped steel, angle steel, etc. to enhance the stability of engineering structures. They are generally inclined connecting members, the most common ones being herringbone and cross shapes. Steel supports are widely used in subways and foundation pit enclosures. Because steel supports can be recycled and reused, they are economical and environmentally friendly

Parameters

| LIGHT DUTY PROPS | ||||

| Adjustable Heightht | Outter Tube | Inner Tube | Top and Base Plates | Weight(+/-3%) |

| 600-1100mm | 48*1.5mm | 40*1.5mm | 120*120*4.0mm | 3.8kg/PC |

| 900-1400mm | 48*1.5mm | 40*1.5mm | 120*120*4.0mm | 4.23kg/PC |

| 1200-1700mm | 48*1.5mm | 40*1.5mm | 120*120*4.0mm | 4.66kg/PC |

| 1600-3000mm | 48*1.6mm | 40*1.6mm | 120*120*4.0mm | 7.10kg/PC |

| 1800-3200mm | 48*1.6mm | 40*1.6mm | 120*120*4.0mm | 7.40kg/PC |

| 2000-3500mm | 48*1.8mm | 40*1.8mm | 120*120*4.0mm | 8.60kg/PC |

| MIDDLE DUTY PROPS | ||||

| Adjustable Heightht | Outter Tube | Inner Tube | Top and Base Plates | Weight(+/-3%) |

| 1800-3200mm | 56*1.8mm | 48*1.8mm | 120*120*4.5mm | 9.68kg/PC |

| 2000-3500mm | 16*1.8mm | 48*1.8mm | 120*120*4.5mm | 10.33kg/PC |

| 2000-3600mm | 56*1.8mm | 48*1.8mm | 120*120*4.5mm | 10.57kg/PC |

| 2200-4000mm | 56*2.0mm | 48*2.0mm | 120*120*4.5mm | 12.44kg/PC |

| HEAVY DUTY PROPS | ||||

| Adjustable Heightht | Outter Tube | Inner Tube | Top and Base Plates | Weight(+/-3%) |

| 2000-3600 | 60*2.0 | 48*2.0 | 120*120*5.0 | 11.71kg/PC |

| 2200-3900 | 60*2.0 | 48*2.0 | 120*120*5.0 | 12.45kg/PC |

| 2200-4000 | 60*2.0 | 48*2.0 | 120*120*5.0 | 12.74kg/PC |

| 2400-3900 | 60*2.0 | 48*2.0 | 120*120*5.0 | 12.33kg/PC |

| 2400-4000 | 60*2.0 | 48*2.0 | 120*120*5.0 | 12.62kg/PC |

| 3000-5500 | 60*2.0 | 48*3.0 | 120*120*5.0 | 23.60kg/PC |

| 3300-6000 | 60*2.0 | 48*3.0 | 120*120*5.0 | 25.50kg/PC |

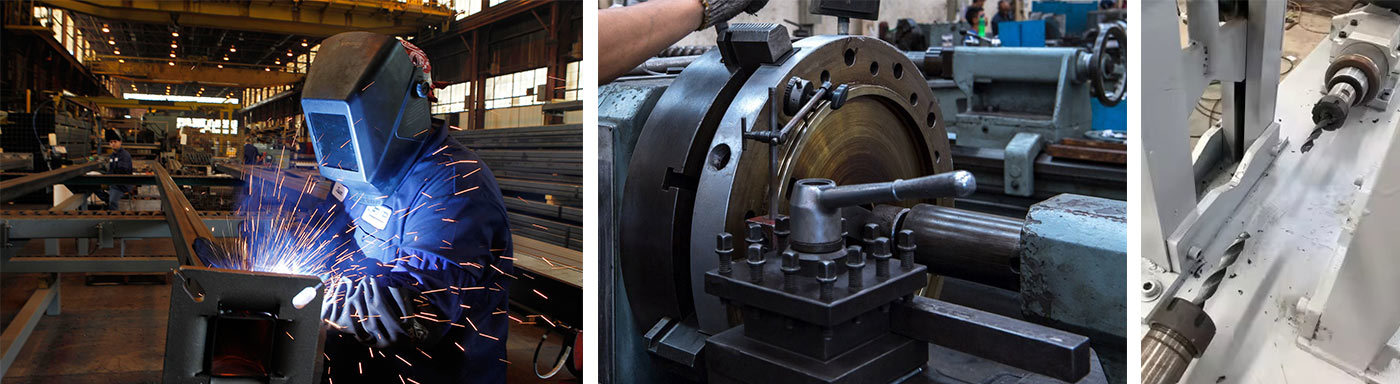

Production Process

1. Material selection

The materials used for steel supports mainly include steel pipes, angle irons, I-beams, etc., which require strong quality and a smooth surface without rust. When selecting steel pipes, pay attention to the matching of diameter and wall thickness. When selecting angle iron or I-beam, the cross-sectional area is required to be at least 5-6 times that of the support.

2. Make templates

Before making steel supports, it is necessary to determine the main shape and size of the supports according to the design drawings, and make the corresponding templates. The template can be made of wooden boards or cardboard, and the accuracy is determined according to the requirements of the design drawings to ensure that the dimensional accuracy and shape of the produced steel support meet the requirements.

3. Processing

Next, the processing of steel pipes, angle irons, I-beams, etc. is carried out. Steel pipes are required to be cut vertically, without burrs, and have smooth end faces. Angle irons and I-beams also need to be bent and sheared to ensure that they meet the requirements of the design drawings.

4. Welding

Welding is one of the key aspects in making steel supports and its importance cannot be underestimated. Before welding, materials such as steel pipes and angle irons need to be surface treated to remove rust, oil and other impurities to ensure welding quality and strength. During the welding process, the temperature and welding speed must be strictly controlled to ensure that the welded joint is firm and without cracks.

5. Surface treatment

After welding is completed, the steel supports also need to be surface treated. It mainly includes anti-rust, spray painting and other processes to extend the life and beauty of the steel support.

In addition to the above-mentioned links in the entire steel support production process, you also need to pay attention to safety. Pay attention to the use of protective equipment during processing, welding and other links to avoid injuries.

Application description

Uses of steel supports

1. Building construction supports: In construction, steel supports can be used to support buildings under construction, bear temporary loads and forces, and maintain the safety and stability of the construction site.

2. Road construction supports: Steel supports are also widely used in road construction to support structures such as road bridges, tunnels, cable racks adjacent to roads, sound insulation panels and sound barriers to maintain traffic safety.

3. Bridge construction and repair: In bridge construction and repair, steel support systems can be used to temporarily support beams, bottom plates and piers to improve the efficiency of bridge construction and repair.

4. Tunnel construction supports: Similar to bridges, steel supports are used to support the tunnel walls, top and bottom during tunnel construction to provide safe support.

Shipping Packaging

products are sold all over the country and Europe, America, the Middle East, Africa and Southeast Asia and other global more than 100 countries,and the world's top 500 enterprises to establish a deep cooperative relationship, well received by customers.

Customer visit

We uphold the customer-centric business philosophy, and win the trust of customers with high-quality products, considerate service, and punctual delivery. We sincerely welcome domestic and foreign merchants to visit us, seek common development, and create brilliance together!

INTENTION INFORMATION

Related Products

GET A FREE QUOTE