FRP grating

Classification :

Carbon steel plate

PRODUCT DETAILS

Product Description

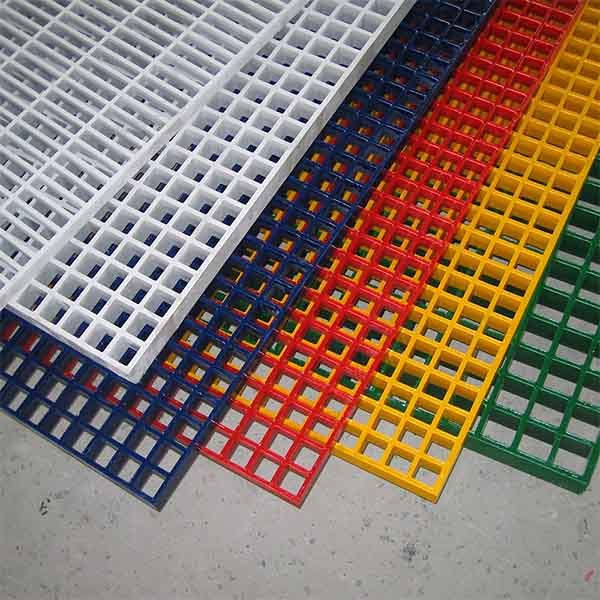

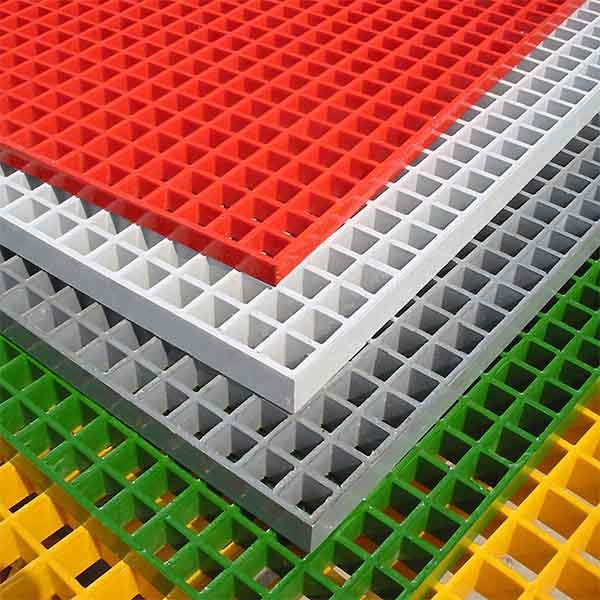

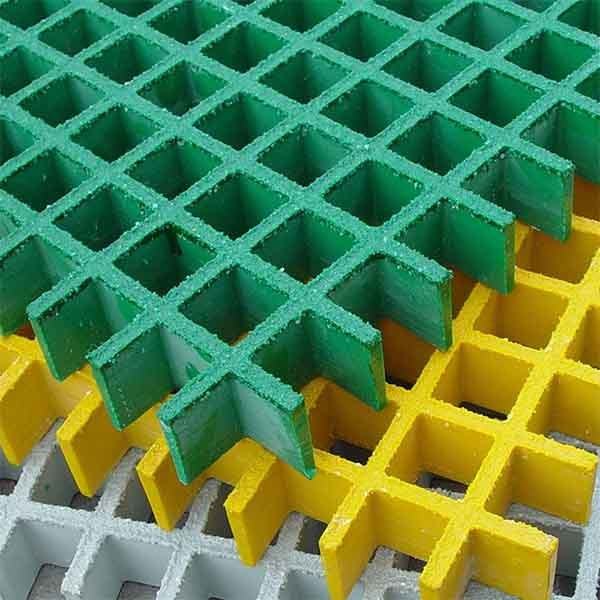

Glass fiber reinforced plastic (FRP) grating, also known as FRP grating, is a plate-shaped material with many spaces that is made of glass fiber as a reinforcing material and unsaturated polyester resin as a matrix. It is compounded through special processing. Fiberglass grating can be used as structural materials for floors, trench covers, platforms, ship decks, stairs, planks, etc. in corrosive environments. It has the characteristics of corrosion resistance and flame retardancy, non-magnetic insulation, bright colors, and a variety of styles to choose from.

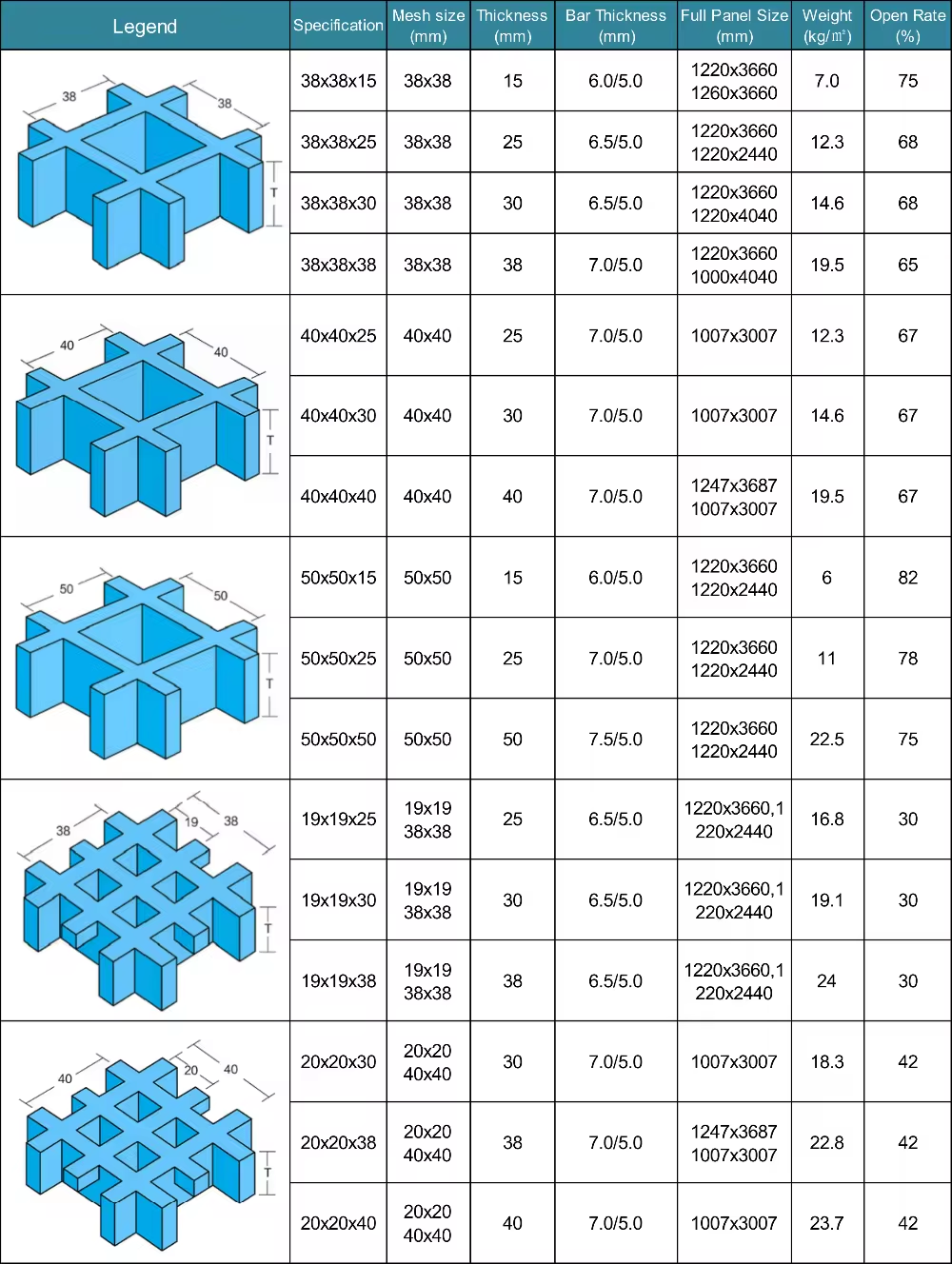

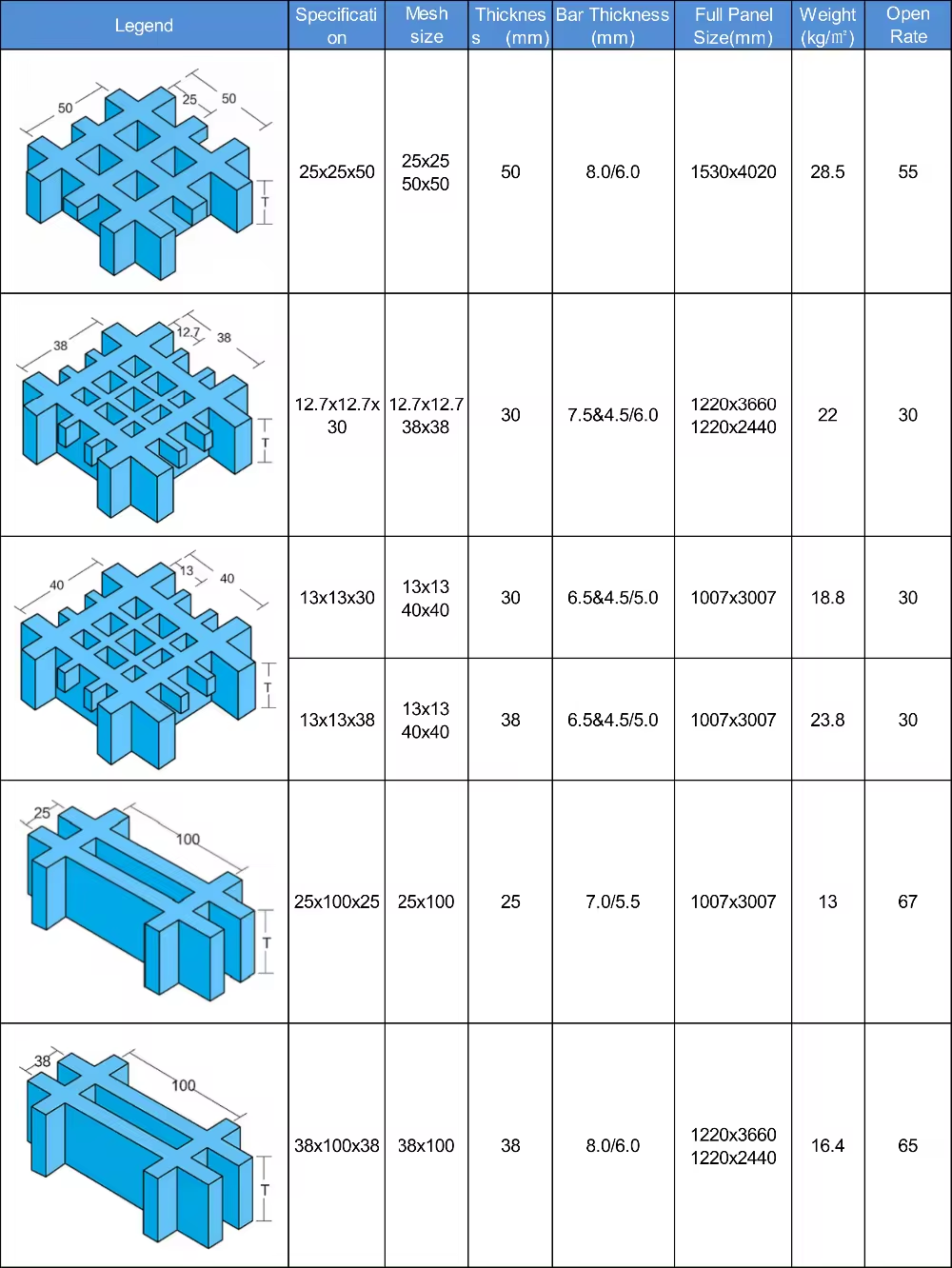

Parameters

| Product name | FRP grating |

| Material | Fiberglass + Resin base (ORTHO,ISO,VE) |

| Size | 38*38*38mm,40*40*40mm, etc. can be customized |

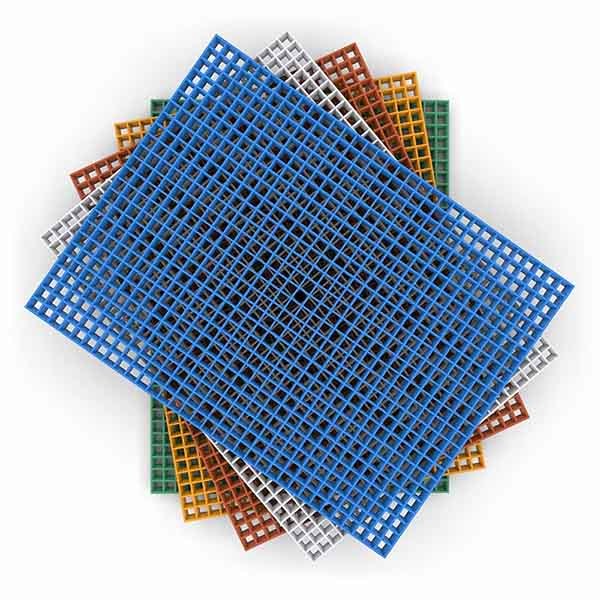

| Color | Yellow, Orange, Blue, Green, Grey, etc. can be cutomized |

| Surface treatment | Gritted |

Production Process

There are three main types of FRP grating production processes: reciprocating fiber winding process, continuous fiber winding process and centrifugal casting process.

Reciprocating fiber winding process (belonging to the fixed-length method): In this process, the dipping tank reciprocates with the rotating mandrel, and the long fiber glass filaments are placed at a certain oblique angle relative to the mandrel axis, and the auxiliary angle (i.e. The winding angle) is controlled by the ratio of the moving speed of the dipping tank and the rotation speed of the mandrel, and the translational movement of the dipping tank is controlled by computerized electromechanical control. The number of winding layers is gradually increased until the designed wall thickness is reached. After winding is completed, the resin in the product is basically solidified. After curing, the mandrel is removed from the fiberglass tube.

Continuous fiber winding process (belongs to the continuous method): In this process, the pipe moves through a feeding station that supplies a mixture of resin pre-impregnated roving, chopped fiberglass fiber and resin sand. The pipe continuously advances in the mandrel. Made in.

Centrifugal casting process (fixed-length method): In this process, cut glass fiber reinforced materials and sand are fed into a steel mold fixed on the bearing, and unsaturated resin with a catalyst is injected into one end of the steel mold to make it It is impregnated with reinforcing materials. Under the action of centrifugal force, the resin displaces the air in the fibers and fillers, thereby creating a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the pipe forms a smooth and smooth resin-rich inner surface layer. The pipe Cure at higher temperatures. The pipe made by this method is also called fiberglass sand-filled pipe.

Shipping Packaging

products are sold all over the country and Europe, America, the Middle East, Africa and Southeast Asia and other global more than 100 countries,and the world's top 500 enterprises to establish a deep cooperative relationship, well received by customers.

Application description

The grating is made of fiberglass interwoven and integrally molded by resin casting. The fiberglass grating plate produced has many regularly distributed rectangular and square spaces, which has bidirectional mechanical characteristics. It can be widely used in working platforms, equipment platforms, drilling platforms, walkways, etc. in industries such as petroleum, chemical electronics, electricity, paper, printing and dyeing, electroplating, ocean exploration, sewage treatment, etc. It is an ideal product in corrosive environments and is also suitable for On civil construction facilities.

Customer visit

We uphold the customer-centric business philosophy, and win the trust of customers with high-quality products, considerate service, and punctual delivery. We sincerely welcome domestic and foreign merchants to visit us, seek common development, and create brilliance together!

INTENTION INFORMATION

Related Products

GET A FREE QUOTE