Steel grille plate

Classification :

Carbon steel plate

PRODUCT DETAILS

Product Description

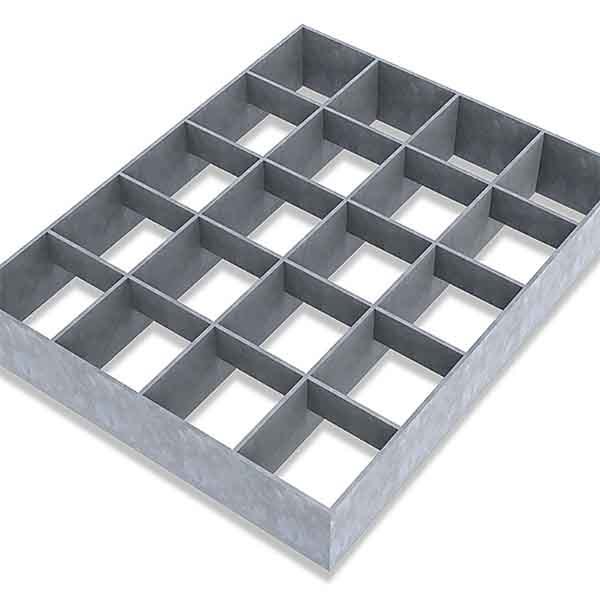

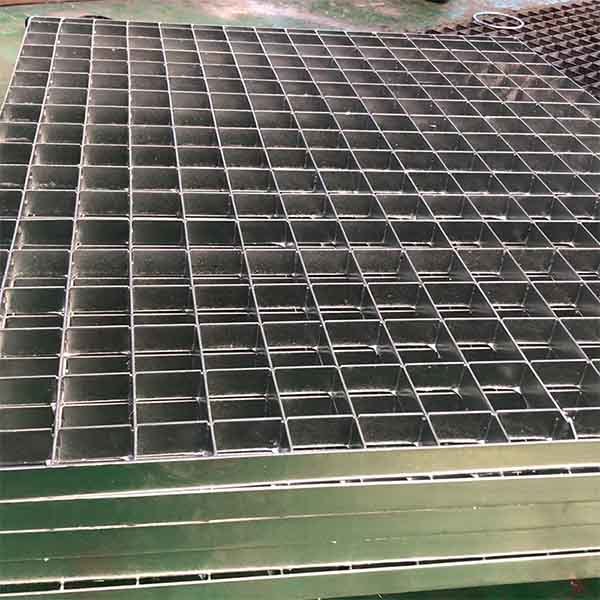

Steel grating is also called steel grating. The grating is a steel product made of flat steel arranged crosswise with horizontal bars at certain intervals and welded into a square grid in the middle. It is mainly used to make ditch covers. , steel structure platform plates, steel ladder treads, etc. The cross bars are generally made of twisted square steel.

Parameters

| Product name | Steel grille plate |

| Material Standard | ASTM A36, A1011, A569, Q235, S275JR, Stainless steel 304/316, Mild steel & Low carbon steel, etc |

| Bearing Bar (Width x Thickness) |

25x3, 25x4, 25x4.5, 25x5, 30x3, 30x4, 30x4.5, 30x5, 32x5, 40x5, 50x5, 65x5, 75x6, 75x10…..100 x10mm etc; I bar: 25x5x3, 30x5x3, 32x5x3, 40x5x3 etc US standard: 1"x3/16", 11/4"{x3/16", 11/2"x3/16", 1"x1/4", 11/4"x1/4", 11/2"x1/4", 1"x1/8", 11/4"x1/8", 11/2"x1/8" etc |

| Bearing Bar Pitch | 12.5, 15, 20, 23.85, 25, 30, 30.16, 30.3,32.5, 34.3, 35, 38.1, 40, 41.25, 60, 80mm etc. US standard: 19-w-4, 15-w-4, 11-w-4, 19-w-2, 15-w-2 etc. |

| Twisted Cross Bar Pitch | 38.1, 50, 60, 76, 80, 100, 101.6, 120mm, 2'' & 4'' etc |

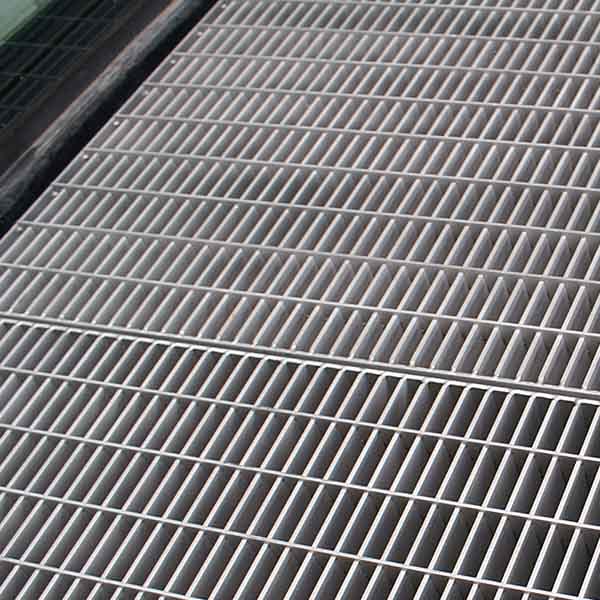

| Surface Treatment | Untreated(black), Hot-dipped galvanized, Powder coated, Electroplate, Painting or as per customers' requirement. |

| Grating Style | Plain / Smooth, Serrated / Teeth, I bar, Serrated I bar |

| Packing | (1) Bandage and Paperboard: Generally applies to neat steel plate; (2) Screw Locking Method: Use 4 screw rods through the aperture of the steel grid, for high strength; (3) Steel Pallet: Traditional export packing. |

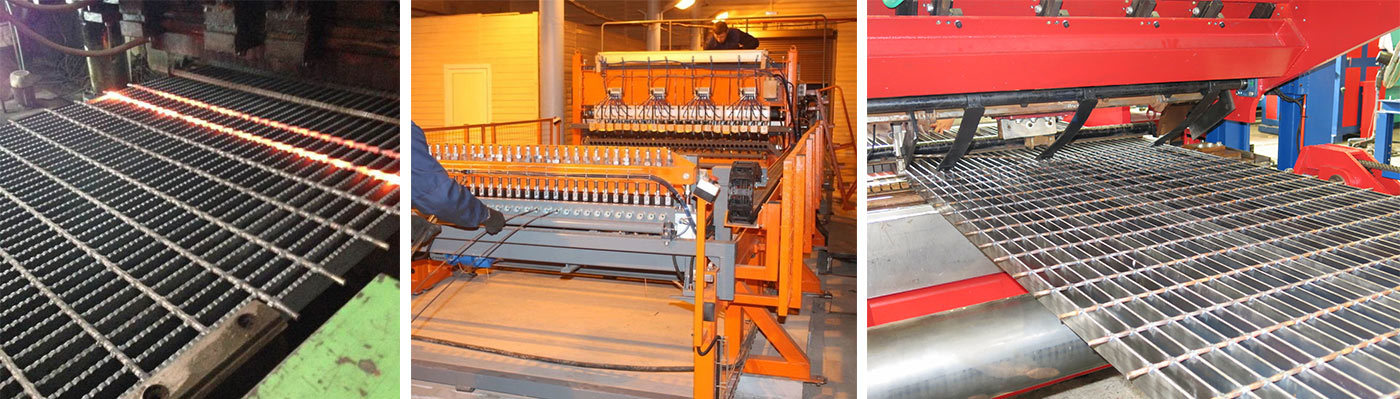

Production Process

1. The pressure-welded steel grating plate is made of load-bearing flat steel and cross bars arranged at a certain distance and welded into the original plate using 200 tons of hydraulic resistance welding automation equipment. It is processed by cutting, drilling, hemming and other processes to meet customer requirements. The product.

2. Spacing between loaded flat steels: the center distance between two adjacent loaded flat steels, commonly used are 30MM and 40MM.

3. Crossbar spacing: The center spacing between two adjacent crossbars is usually 50MM or 100MM, and can be produced according to customer requirements.

4. Various types of steel gratings can be customized according to customer requirements.

Shipping Packaging

products are sold all over the country and Europe, America, the Middle East, Africa and Southeast Asia and other global more than 100 countries,and the world's top 500 enterprises to establish a deep cooperative relationship, well received by customers.

Application description

Widely used in platforms, walkways, trestles, trench covers, manhole covers, ladders, fences, factories in the fields of petrochemical industry, electric power, tap water, sewage treatment, ports and terminals, building decoration, shipbuilding, self-propelled parking lots, municipal engineering, sanitation projects, etc. Construction etc.

Customer visit

We uphold the customer-centric business philosophy, and win the trust of customers with high-quality products, considerate service, and punctual delivery. We sincerely welcome domestic and foreign merchants to visit us, seek common development, and create brilliance together!

INTENTION INFORMATION

Related Products

GET A FREE QUOTE